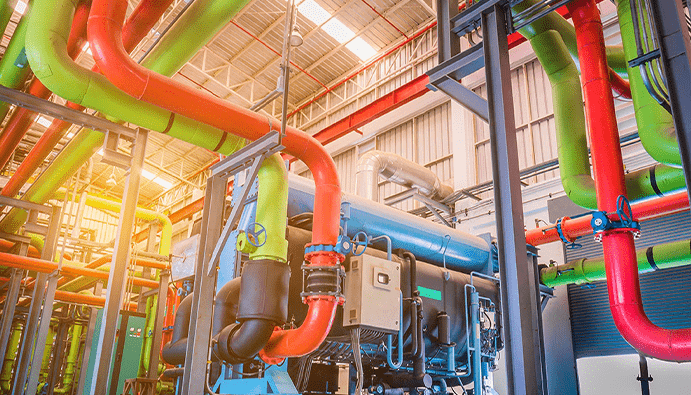

Mechanical Equipment & Online Monitoring: Comprehensive Environmental Solutions for 2025

1. Online Monitoring Systems – The 24/7 "Guardian"

Automatic and continuous monitoring is not just a mandatory requirement for industrial parks starting in 2025; it is also a powerful leap in digital transformation. This technology is a perfect intersection of mechanical engineering, analytical sensors, and IoT platforms.

Smart Operating Principles:

-

Sampling: Wastewater is extracted via metering pumps and specialized sampling lines.

-

Analysis: Sensors continuously measure key parameters such as pH, COD, BOD, TSS, DO, etc.

-

Transmission: Data is digitized and transmitted directly to the Department of Natural Resources and Environment (DONRE) in real-time via 4G/Internet connectivity.

-

Alerts: The system automatically triggers instant notifications if any indicator exceeds the threshold, allowing businesses to respond proactively to risks.

2. Essential Mechanical Equipment and Analytical Sensors

An effective environmental protection system requires both mechanical durability and sensor precision:

-

DO, pH, and TSS Sensors: Monitor dissolved oxygen, acidity/alkalinity, and suspended solids to optimize biological treatment and sedimentation processes.

-

Optical Technology (UV-Vis): Enables instantaneous online COD and BOD measurement, eliminating the need for complex and time-consuming manual sampling.

-

Automatic Samplers: Constructed from high-grade stainless steel (SUS304/316) to ensure corrosion resistance and maintain accurate composite samples for regulatory verification.

3. 2025 Environmental Technology Trends

2025 marks a major turning point with two leading trends:

-

AI & Big Data: Transitioning from "monitoring" to "prediction." Systems can now analyze big data to forecast potential violation risks before they occur.

-

Automated Sensors: Next-generation devices feature self-cleaning and self-calibration capabilities, significantly reducing maintenance costs and manual labor.

-

Mandatory Roadmap: Effective January 1st, 2025, 100% of industrial parks must complete the installation of online monitoring systems, creating a transparent national environmental data network.

4. Strategic Benefits for Enterprises

Investing in modern mechanical and monitoring equipment provides value far exceeding the initial cost:

-

Regulatory Shield: Ensures absolute legal compliance, avoiding massive administrative fines or operational suspension.

-

Operational Optimization: Reduces labor and chemical costs through the accuracy of real-time data.

-

Brand Reputation: Data transparency helps businesses achieve ESG certifications, creating a competitive edge in international markets.

5. Challenges and Adaptation

Despite challenges regarding initial Capital Expenditure (CAPEX) and the need for highly skilled technical personnel, this is a worthy investment for the future. Businesses should partner with reputable equipment providers that offer robust maintenance programs to ensure system stability in harsh wastewater environments.

Conclusion

Online wastewater monitoring and modern mechanical equipment are the inevitable future of the environmental sector in the digital age. This is not merely a management tool but a testament to corporate social responsibility.

Let technology become the "shield" that protects your business while we work together to build a sustainable green planet!

Tác giả: Phạm Quốc Tiến

Những tin cũ hơn

Online Wastewater Monitoring Systems: A Key Solution for Environmental Management in 2025

Real-time wastewater monitoring provides 24/7 oversight, meets the latest regulations, and helps enterprises manage the environment with greater intelligence and transparency.

Tin xem nhiều

Key Updates: Decree 05/2025/ND-CP vs. Decree 08/2022/ND-CP

Industrial Exhaust Gas Treatment: Comprehensive Solutions for Businesses and the Environment in 2025

Application of Mechanical Technology in Wastewater Treatment: Solutions for Modern Enterprises

Online Wastewater Monitoring Systems: A Key Solution for Environmental Management in 2025

Treatment of Natural Water Sources

Chocolate Production and Its Environmental Impact

Expatriates Leave Hanoi Due to Severe Air Pollution

Advanced Wastewater Treatment Workflow and Contaminant Removal Efficiency

Vietnam Reduces 240 Million Tons of CO2e Emissions