Industrial Exhaust Gas Treatment: Comprehensive Solutions for Businesses and the Environment in 2025

What are environmental emissions?

Environmental emissions are gases, vapors, or dust released from production activities, transportation, or energy consumption that can cause environmental pollution and impact human health. Common types of environmental emissions include CO2, SOx, NOx, vehicle exhaust, and particulate matter...

Manufacturing plants, thermal power stations, craft villages, industrial parks, and industrial clusters are releasing large quantities of toxic gases such as CO2, SO2, and NOx, which lead to the greenhouse effect, acid rain, and respiratory issues. To combat this situation, businesses must invest in modern emission treatment technologies and apply strict environmental standards.

1. The Importance of Environmental Exhaust Gas Treatment

Effective exhaust gas treatment provides numerous practical benefits, ranging from protecting public health against air pollution-related diseases to minimizing negative environmental impacts such as the greenhouse effect and acid rain. Furthermore, compliance with environmental protection regulations helps build a positive image for both businesses and the community.

Additionally, according to Clause 1, Article 4 of Decree No. 45/2022/ND-CP, businesses committing administrative violations in the field of environmental protection may face fines of up to 2 billion VND per violation. Besides monetary penalties, businesses may also receive warnings or be required to implement specific remedial measures to address the consequences.

2. The Importance of Installing an Emission Treatment System

Commonly used methods for environmental exhaust gas treatment include:

Treatment of Dust-Laden Exhaust Gas

Production processes such as crushing, grinding, and mixing raw materials in industries like cement manufacturing and ore processing often generate large volumes of dust, leading to severe environmental pollution. If not thoroughly treated, this dust not only adversely affects the health of workers but also causes significant harm to the surrounding environment.

/xu-ly-khi-thai-3.webp)

Dust Removal in High-Concentration Exhaust Gas

To treat exhaust gas with a high dust content, the standard approach is to separate the particles from the gas stream. This dust separation is typically achieved through several measures, such as:

Cyclone Separators

Cyclone units are widely used in various exhaust gas treatment systems, playing a crucial role in the pre-treatment stage to separate large volumes of dust from the emission stream.

/xu-ly-khi-thai-4.webp)

Baghouse Filters (Fabric Filters)

With high filtration efficiency, ease of construction, and reasonable costs, baghouse filters have become a leading popular solution in industrial exhaust gas treatment systems.

/xu-ly-khi-thai-5.webp)

Electrostatic Precipitation (ESP)

Electrostatic precipitators (ESPs) are commonly used to treat gas systems that generate high volumes of fine dust, such as those found in thermal power plants or coal-fired boilers.

/xu-ly-khi-thai-6.webp)

Electrostatic precipitation is one of the optimal methods.

Exhaust Gas Treatment using Adsorption Towers

The adsorption method using specialized media is commonly employed to treat exhaust gases containing solvent vapors or odors. This method is highly efficient, with treatment effectiveness reaching 90% to 98%.

/xu-ly-khi-thai-7.webp)

Operating Principle of Exhaust Gas Treatment by Adsorption

Using Activated Carbon

The activated carbon adsorption tower method is commonly applied in industrial printer manufacturing and small-capacity heating chambers. This method is characterized by its ability to treat small volumes of exhaust gas with low pollutant concentrations.

Adsorption Using Solid Materials

Solid materials possess the ability to chemically react with exhaust gases. Common adsorbents include Silica gel and Zeolites. However, this method is typically used only for treating emissions containing a specific pollutant or in processes such as gas recovery, gas drying (e.g., oxygen, natural gas), and the adsorption of heavy (polar) hydrocarbons from natural gas.

Despite its advantages, this method has not yet been widely applied in practical industrial settings.

Exhaust Gas Treatment using Absorption Towers

The absorption tower treatment method (or wet scrubbing) is applied to treat exhaust gases containing chemical pollutants, fine dust, or smoke. It is commonly used in industries such as boiler emission control, copper and aluminum smelting, acid fume neutralization, and kiln operations.

/xu-ly-khi-thai-8.webp)

Exhaust gas treatment by absorption method

In an absorption tower (scrubber), the gas stream is introduced at the bottom, while the absorbent solution is pumped from a storage tank to the top and sprayed into fine liquid droplets within the unit. The absorption tower consists of two structured stages, each performing a specific role in the treatment process.

Combining Absorption and Adsorption

This approach is applied to exhaust gases containing cyclic or aromatic organic compounds. To treat the initial emissions, an absorption stage is utilized. Subsequently, to achieve higher efficiency, an additional adsorption step is implemented. The specifics of this process have been detailed by ETM in the previous sections regarding the absorption and adsorption processes.

/xu-ly-khi-thai-9.webp)

Kết hợp 2 phương pháp để đạt hiệu quả cao hơn

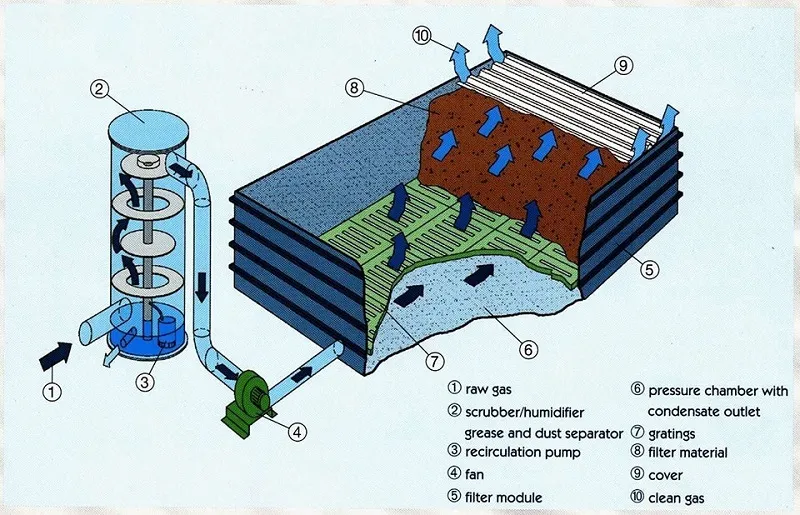

Biofiltration Method (Biofilter)

The biofiltration method, also known as Biofilter technology, is an effective solution for odor control. This method is particularly suitable for wastewater treatment systems due to its low investment costs, simple operation, and environmental friendliness. It is primarily used to treat odorous gases and volatile organic compounds (VOCs) at low concentrations.

Exhaust gas treatment using biotechnology

3. Exhaust Gas Treatment in Industrial Sectors

Exhaust gas treatment is a critical issue across various sectors, including manufacturing, power generation, and transportation. In the manufacturing industry, emissions typically arise from production processes and contain toxic compounds such as CO, SOx, NOx, volatile organic compounds (VOCs), methane, ammonia, and heavy metals.

To treat emissions in manufacturing, various technologies are utilized, such as absorption, adsorption, oxidation, scrubbing, biofiltration, and combustion.

In the power generation industry, emissions commonly include SOx, NOx, and carbon compounds. Treatment technologies in this sector include chemical treatment, scrubbing, biofiltration, and combustion.

In general, all industrial sectors must implement exhaust gas treatment measures to minimize their impact on the environment and human health. Selecting the appropriate treatment technology requires careful consideration to ensure both operational efficiency and cost-effectiveness.

4. Applications of Exhaust Gas Treatment Methods

Exhaust gas treatment methods have diverse applications across various sectors, including:

-

Manufacturing Industries: Industrial zones, industrial clusters, and manufacturing plants.

-

Power Generation: Thermal power plants and hydroelectric power plants.

-

Craft Villages: Traditional production communities.

In general, applying effective environmental exhaust gas treatment methods not only minimizes negative impacts on the environment but also helps businesses save costs and enhance market competitiveness.

However, choosing a reputable contractor for the construction and installation of exhaust gas treatment systems is no simple task. To ensure treatment efficiency, durability, and system sustainability, it is essential to select providers with proven experience, professional technical teams, and a commitment to quality standards and environmental safety.

Therefore, businesses should contact a reputable specialist in exhaust gas treatment systems, such as ETM, via hotline 0923 392 868 to ensure project progress, quality, and long-term sustainability. This is a concrete contribution by businesses toward a green and sustainable environment, joining hands with society to build a better world.

Tác giả: AISVy

Những tin cũ hơn

Advanced Wastewater Treatment Workflow and Contaminant Removal Efficiency

Hands-on with the DJI Osmo 360 (Rumored): DJI's first 360° camera featuring groundbreaking specs such as 8K 50fps video, dual 1-inch HDR sensors, and up to 100 minutes of continuous recording

Key Updates: Decree 05/2025/ND-CP vs. Decree 08/2022/ND-CP

On January 6, 2025, the Government issued Decree No. 05/2025/ND-CP, amending and supplementing several articles of Decree No. 08/2022/ND-CP. Below is a summary of the new points in Decree 05 compared to Decree 08 regarding environmental protection.

Application of Mechanical Technology in Wastewater Treatment: Solutions for Modern Enterprises

The application of modern mechanical technology in wastewater treatment helps businesses save costs, meet environmental standards, and improve production efficiency.

Những tin mới hơn

Treatment of Natural Water Sources

Water treatment is the process of treating raw water through a specialized system to remove mineralized components, impurities, sediments, and microorganisms that are harmful to human health. After treatment, the purified water is distributed through water supply stations before being delivered to residential areas, commercial enterprises, and manufacturing plants.

Chocolate Production and Its Environmental Impact

A recent study published in the journal Science Advances has shed light on key ingredients in many chocolate products that are often overlooked yet linked to deforestation across Latin America, Africa, and Asia.

Expatriates Leave Hanoi Due to Severe Air Pollution

Despite an 8-year bond and a deep love for Hanoi, William Gray eventually moved his entire family away, unable to endure an atmosphere "thick with vehicle exhaust and the stench of burning plastic."

Vietnam Reduces 240 Million Tons of CO2e Emissions

In the context of rapid industrialization and urbanization, issues regarding emission treatment and ventilation in factories, mines, buildings, and industrial parks have become extremely urgent. One of the widely applied environmental engineering solutions is the industrial Axial Fan.

Tin xem nhiều

Key Updates: Decree 05/2025/ND-CP vs. Decree 08/2022/ND-CP

Application of Mechanical Technology in Wastewater Treatment: Solutions for Modern Enterprises

Online Wastewater Monitoring Systems: A Key Solution for Environmental Management in 2025

Mechanical Equipment & Online Monitoring: Comprehensive Environmental Solutions for 2025

Chocolate Production and Its Environmental Impact

Vietnam Reduces 240 Million Tons of CO2e Emissions

Treatment of Natural Water Sources

Advanced Wastewater Treatment Workflow and Contaminant Removal Efficiency

Expatriates Leave Hanoi Due to Severe Air Pollution