Advanced Wastewater Treatment Workflow and Contaminant Removal Efficiency

1. What is Wastewater Treatment?

Wastewater treatment is the process of removing contaminants from wastewater before it is discharged into the environment or reclaimed for reuse. Wastewater originates from various sources, including municipal, industrial, agricultural, and medical activities. If left untreated, it can pollute water bodies, severely impacting human health and ecosystems. Once treated, the water meets environmental quality standards, ensuring the safety of water resources. Furthermore, treated wastewater can be repurposed for various applications, such as irrigation and vehicle washing.

It is fair to say that wastewater treatment is an essential activity in the face of rising water pollution. Thanks to modern treatment solutions, we can effectively eliminate toxins, bacteria, and other contaminants from wastewater before it is discharged into the environment or reclaimed for reuse. This is an indispensable effort in protecting human health and ecosystems, while ensuring a sustainable future for generations to come.

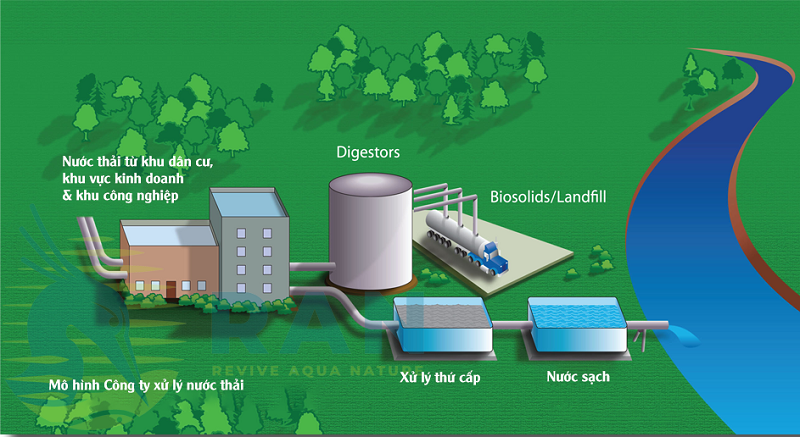

2. Overview of Wastewater Treatment Systems

In essence, a wastewater treatment system is a strategic integration of individual technologies into a comprehensive workflow, specifically engineered to address the unique wastewater challenges of each business.

For instance, if you require medical wastewater treatment for facilities such as hospitals, medical centers, or clinics, the AAO-MBR hybrid technology is an ideal solution. This advanced biological treatment system is currently one of the most widely adopted technologies across the healthcare sector.

A treatment system is a dynamic process; it is adaptable to specific needs rather than a 'one-size-fits-all' solution. An efficiently designed and high-performing treatment system must satisfy the following requirements:

-

Present-day Performance: Effectively treats wastewater according to user requirements, ensures effluent meets regulatory standards, and maintains reasonable installation and operational costs.

-

Future-proofing: Adapts to fluctuations in treatment demands, including changes in flow rates, wastewater composition, regulatory updates, and chemical requirements. This proactive approach helps avoid the high costs of total system replacement or major equipment upgrades.

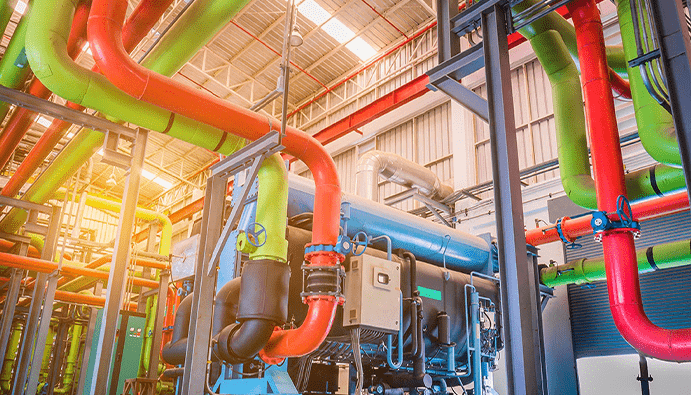

3. Basic Components of a Wastewater Treatment System

To accurately determine the components of a treatment system, it is essential to analyze the specific characteristics of the wastewater and the discharge standards regulated by the authorities. Basically, a wastewater treatment system includes:

-

Sedimentation Tanks & Bar Screens: Used to remove suspended solids throughout the treatment process.

-

Water Pumps: Used to control and regulate the flow of wastewater during various treatment stages.

-

Chemical Dosing Systems: Used to facilitate coagulation, flocculation, and precipitation processes to remove organic and inorganic matter, fine suspended solids, or heavy metals

-

Filtration: Applied to remove remaining suspended solids from the wastewater. The selection of filtration equipment depends strictly on specific discharge standard regulations.

-

pH Adjustment: Performed during the chemical treatment stage. Adjusting the pH level is essential to ensure the maximum efficiency of chemical reactions throughout the treatment process.

-

Control Panel (Electrical Control Cabinet): Used for the automated control and operation of the entire treatment system.

The components above fulfill the requirements of a basic wastewater treatment system. However, for enterprises with more demanding treatment needs, additional technologies or enhanced features may be integrated into various stages.

For instance, in the food and beverage or fruit juice industry, the system must focus heavily on organic matter removal. Therefore, careful consideration and investment in specialized components for the biological treatment stage are crucial.

4. Common Pollutants Removed During Wastewater Treatment

Our wastewater treatment systems are specifically engineered to eliminate the following contaminants:

-

Heavy Metals: Primarily found in effluent from metallurgy, electroplating, and mining activities. If left untreated, these metals accumulate in the environment, causing persistent pollution and posing severe health risks to humans and aquatic ecosystems.

-

Pathogens: These include bacteria, viruses, fungi, and other microorganisms. Untreated wastewater can become a vector for waterborne diseases, leading to outbreaks of cholera, bacterial infections, hepatitis, and other infectious conditions.

-

Nitrates and Phosphates: High concentrations of nitrates and phosphates can increase the BOD (Biochemical Oxygen Demand) in water bodies, triggering rapid algae and plankton growth. This leads to eutrophication, depleting dissolved oxygen levels and creating "dead zones" where aquatic life cannot survive.

-

Biochemical Oxygen Demand (BOD): High BOD levels in wastewater deplete the dissolved oxygen available in water bodies, severely threatening the survival of aquatic organisms.

-

Total Dissolved Solids (TDS): Untreated TDS can harm aquatic life, damage irrigation systems, and reduce crop yields. Furthermore, dissolved solids can leach into groundwater sources, posing long-term risks to human health.

-

Total Suspended Solids (TSS): TSS reduces oxygen levels in the water, adversely affecting aquatic species. Additionally, high TSS can lead to sedimentation, clogging, and foul odors within piping and treatment equipment.

-

Synthetic Chemicals: This category includes hazardous chemicals that can cause endocrine disruption and other severe health issues in humans and wildlife. Examples include pesticides, dioxins, DDT, PCBs, and other toxic chemical compounds.

Our wastewater treatment systems are rigorously designed to remove and minimize these contaminants, ensuring the protection of both the environment and public health.

5. Basic Wastewater Treatment Process

The operational workflow of a standard wastewater treatment system generally consists of the following stages:

Preliminary Treatment Stage

- Wastewater enters the system and passes through bar screens (trash racks) to remove large debris and solids.

- Collected waste is separated and disposed of properly, typically through landfilling or other compliant disposal methods.

- Wastewater is then pumped from the collection tank to the sedimentation tank for further processing.

Primary Treatment Stage

- Wastewater flows slowly into the primary clarifier (sedimentation tank). Here, lighter substances such as oils, fats, grease, and plastics float to the surface and are removed by skimming.

- Organic solids and sludge (such as fecal matter, paper fibers, and food particles) settle to the bottom of the tank.

- The settled sludge is pumped out, thickened, and decomposed through a dedicated treatment process.

Secondary Treatment Stage

This stage involves two key biological processes:

- Aerobic Treatment: In the aeration tank, air is continuously injected to provide an optimal environment for aerobic microorganisms to grow. These microorganisms consume organic matter in the wastewater, converting it into heavier particles (flocs) that are easier to remove.

- Anaerobic/Final Sedimentation: The wastewater flows into a secondary clarifier (final settling tank), where the heavier solids settle to the bottom. Sludge from this stage is collected and combined with primary sludge for final processing.

A portion of the sludge from this stage is recycled back to the aeration tank to maintain a healthy population of aerobic microorganisms for effective wastewater treatment.

Disinfection Stage

Other Specialized Treatment Stages

Sludge and solid waste generated during this process can be managed through various methods, including landfilling, composting for fertilizer, or incineration for energy recovery. Furthermore, depending on the specific industry, specialized treatment may be required to remove heavy metals or complex organic compounds. This ensures that the final effluent strictly complies with Vietnam’s National Technical Regulations for key parameters such as BOD, TDS, and TSS.

6. Affordable, Reliable, and High-Quality Wastewater Treatment Services

ETM Water and Environmental Treatment Technology Joint Stock Company is a leading multi-disciplinary service provider. With over 20 years of experience, we specialize in designing optimal wastewater treatment solutions tailored to the specific needs and operational realities of your business.

We guarantee that treated effluent meets all regulatory standards while maintaining maximum cost-efficiency. Our comprehensive services include:

-

Consulting & System Design: Custom solutions tailored to your industry-specific production and requirements.

-

Construction & Installation: Seamless execution designed to avoid any disruption to your ongoing production activities.

-

Operations & Maintenance: Professional management and routine servicing of equipment.

-

Upgrades & Retrofitting: Enhancing existing systems to align with current needs and standards.

-

Factory-Direct Equipment: Providing high-quality treatment components at competitive wholesale prices.

Backed by a highly skilled and professional team, ETM is committed to delivering excellence and meeting your highest expectations.

Contact ETM today for expert consultation and support! 📞 Hotline: 0923 392 868

Tác giả: AISVy

Những tin cũ hơn

Công Nghệ Bơm Trong Xử Lý Nước Thải – Giải Pháp Hiệu Quả Cho Doanh Nghiệp

Bơm công nghiệp đóng vai trò quan trọng trong xử lý nước thải. Tìm hiểu công nghệ bơm hiện đại giúp tiết kiệm năng lượng và nâng cao hiệu quả vận hành.

Những tin mới hơn

Industrial Exhaust Gas Treatment: Comprehensive Solutions for Businesses and the Environment in 2025

Exhaust gas treatment is not merely a legal obligation; it is a vital "shield" protecting public health and corporate reputation. As environmental regulations become increasingly stringent, finding an advanced yet cost-effective emission control system is a top priority for sustainable development.Explore the modern treatment technologies offered by ETM below to help your business operate sustainably and safely!

Treatment of Natural Water Sources

Water treatment is the process of treating raw water through a specialized system to remove mineralized components, impurities, sediments, and microorganisms that are harmful to human health. After treatment, the purified water is distributed through water supply stations before being delivered to residential areas, commercial enterprises, and manufacturing plants.

Chocolate Production and Its Environmental Impact

A recent study published in the journal Science Advances has shed light on key ingredients in many chocolate products that are often overlooked yet linked to deforestation across Latin America, Africa, and Asia.

Tin xem nhiều

Key Updates: Decree 05/2025/ND-CP vs. Decree 08/2022/ND-CP

Industrial Exhaust Gas Treatment: Comprehensive Solutions for Businesses and the Environment in 2025

Application of Mechanical Technology in Wastewater Treatment: Solutions for Modern Enterprises

Online Wastewater Monitoring Systems: A Key Solution for Environmental Management in 2025

Mechanical Equipment & Online Monitoring: Comprehensive Environmental Solutions for 2025

Chocolate Production and Its Environmental Impact

Vietnam Reduces 240 Million Tons of CO2e Emissions

Treatment of Natural Water Sources

Expatriates Leave Hanoi Due to Severe Air Pollution